Tesla's Structural Integrity Repair focuses on safety and precision using specialized technicians, advanced composite materials, and precise welding for customized repairs. Post-repair testing ensures structural reliability under various conditions, offering owners peace of mind with enhanced vehicle integrity.

Tesla vehicles are renowned for their innovative technology and robust design. However, like any vehicle, they may require structural integrity repairs due to accidents or damage. This article delves into the intricate process of Tesla’s structural integrity repair, highlighting key techniques for effective reinforcement. We explore post-repair strength assessment methods to ensure longevity, empowering owners with knowledge crucial for maintaining these advanced electric vehicles’ safety and structural integrity.

- Understanding Tesla's Structural Integrity Repair Process

- Key Techniques for Effective Structural Reinforcement

- Ensuring Longevity: Post-Repair Strength Assessment

Understanding Tesla's Structural Integrity Repair Process

Tesla’s Structural Integrity Repair process is a meticulous approach to ensuring vehicle safety and structural soundness after an accident. It involves a comprehensive assessment, where specialized technicians meticulously inspect every component, from the frame to individual panels. This methodical evaluation aims to identify any potential weaknesses or damage caused by incidents like fender benders or more severe collisions.

The repair strategy is tailored accordingly, utilizing advanced techniques such as paintless dent repair for minor dings and dents, preserving the vehicle’s original finish. In cases of more significant structural damage, replacement parts are sourced from Tesla’s rigorous quality control process, ensuring they meet the company’s high standards. This meticulous attention to detail guarantees that the repaired vehicle not only looks like new but also maintains its structural integrity, giving owners peace of mind on the road.

Key Techniques for Effective Structural Reinforcement

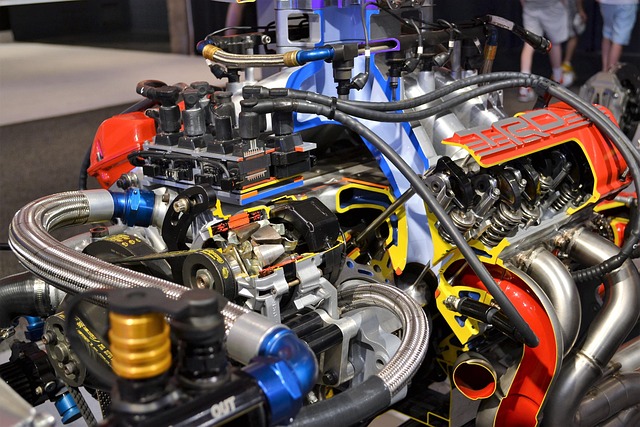

In the realm of Tesla structural integrity repair, effective reinforcement techniques are paramount to ensuring the vehicle’s safety and longevity after damage, whether from an accident or impact. One key approach is the strategic use of composite materials that mimic the original structural properties of the car while providing enhanced durability. These advanced composites, often lighter and more resilient than traditional metals, offer a modern solution for collision repair shops aiming to preserve the vehicle’s performance and aesthetics.

Another vital technique involves precision welding, which demands skill and expertise. Skilled technicians employ this method to rejoin broken components, creating strong bonds that rival the original structure. This meticulous process is especially crucial in high-stress areas of the car body, such as the frame and chassis, where a single weak point can compromise overall structural integrity. For instance, a Mercedes Benz repair may leverage these techniques to restore not just the external dent repair but also the underlying framework, ensuring the vehicle is safe to navigate the bustling roads with unwavering stability.

Ensuring Longevity: Post-Repair Strength Assessment

After completing Tesla structural integrity repair, assessing the post-repair strength is paramount to ensure the longevity and safety of the vehicle. This involves meticulous testing procedures designed to mimic real-world conditions, simulating various forces that a vehicle might encounter on the road. The goal is to guarantee that all structural components have been effectively reinforced, restoring the car to its original—or even enhanced—structural integrity.

Such assessments go beyond mere visual inspections and may include advanced diagnostic tools and load tests. By subjecting repaired areas to controlled stress, technicians can verify that the reinforcement methods employed during Tesla structural integrity repair are adequate. This meticulous approach ensures not only the reliability of the vehicle’s structure but also provides peace of mind for owners, knowing their car is safe and ready to withstand the challenges of everyday driving, just like a meticulously restored vehicle would after collision repair or vehicle restoration services.

Tesla structural integrity repair is a meticulous process that combines advanced techniques with rigorous testing to ensure vehicle safety and longevity. By understanding the key steps, from assessment to reinforcement and post-repair strength evaluation, we can appreciate the significance of structural reinforcement in maintaining Tesla’s reputation for quality and durability. This comprehensive approach ensures that drivers not only experience peace of mind but also benefit from a robust and reliable vehicle structure, even after repairs.