Tesla's distinctive vehicle design, featuring sleek aesthetics and advanced aerodynamics, presents unique challenges in structural integrity repairs due to its compact power trains and integration of lightweight composite materials. Specialized knowledge, tools, and precision work are required to access and repair components without disrupting the vehicle structure or compromising modern features like adaptive suspension and ADAS. Specialized Tesla structural integrity repair services are crucial for successfully navigating these complexities and ensuring optimal performance and safety after damage.

Tesla’s structural integrity repair presents unique challenges due to its innovative vehicle design and electric power train. Unlike conventional cars, Tesla models feature advanced architecture, including battery packs integrated into the chassis, making repairs more complex. This article delves into understanding Tesla’s distinct design, exploring the complexities of EV-specific repairs that require specialized tools and highly skilled technicians. We also navigate regulatory considerations, highlighting the importance of computer-aided design (CAD) for precision engineering to maintain structural integrity after any repair work.

- Understanding Tesla's Unique Vehicle Design and Its Impact on Structural Integrity

- – Exploring the distinct architectural features of Tesla vehicles

- – Challenges posed by advanced technology integration

Understanding Tesla's Unique Vehicle Design and Its Impact on Structural Integrity

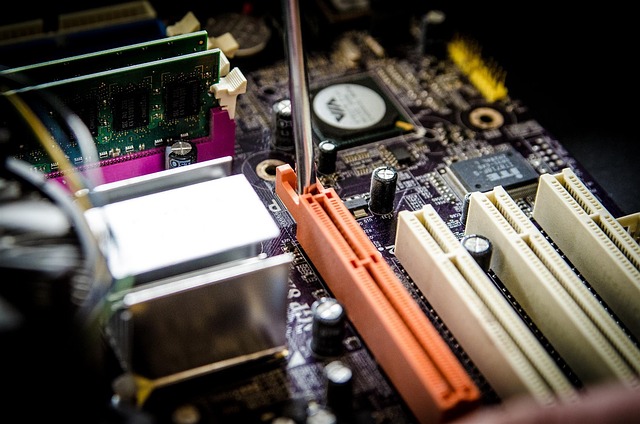

Tesla’s unique vehicle design sets it apart from traditional automotive manufacturers, and this distinctiveness plays a significant role in the complexity of Tesla structural integrity repairs. The company’s electric vehicles (EVs) often feature sleek, streamlined bodies with advanced aerodynamics, which can make them quite different from their internal combustion engine counterparts. This design philosophy emphasizes aesthetics and efficiency, but it also presents unique challenges when addressing structural damage or necessary repairs. For instance, the absence of a conventional engine bay requires specialized knowledge and tools to access and repair certain components without disrupting the overall vehicle structure.

The integration of advanced materials and cutting-edge technologies in Tesla cars further complicates the repair process. The use of lightweight composite materials, such as carbon fiber, is prevalent in Tesla models, offering superior strength and rigidity but also posing unique challenges when damaged. Traditional auto painting and bodywork methods may not be directly applicable, as Tesla repairs often involve intricate precision work to ensure the vehicle’s structural integrity while maintaining its modern, sleek appearance. Car repair services tailored specifically for Tesla vehicles are essential to navigate these complexities successfully.

– Exploring the distinct architectural features of Tesla vehicles

Tesla vehicles are renowned for their innovative design and advanced technology, which goes beyond mere aesthetics. The architectural prowess of Tesla’s engineering team is evident in the intricate layout of various components within their electric cars. Unlike traditional internal combustion engines, Tesla’s power trains are compact and integrated, allowing for a unique distribution of weight and enhanced structural integrity. This distinct feature sets them apart from many other vehicle manufacturers and presents both challenges and opportunities when it comes to Tesla structural integrity repair.

The seamless fusion of battery packs, motors, and control systems within the vehicle’s frame demands meticulous precision during manufacturing and repair processes. When a Tesla experiences damage, whether from a collision or routine auto maintenance, the challenge lies in preserving the delicate balance of these components while ensuring structural integrity is restored to its optimal state. This intricate nature of Tesla’s architecture requires specialized knowledge and equipment, making collision center repairs more complex and requiring skilled technicians adept in handling electric vehicle (EV) specifics.

– Challenges posed by advanced technology integration

The intricate dance of integrating advanced technology into Tesla vehicles presents a unique set of challenges for structural integrity repair. As these electric cars are packed with sophisticated electronics and innovative systems, any damage, especially to the frame or body panels, requires meticulous attention. Standard vehicle repair methods might not be applicable, as altering the delicate balance of these high-tech machines could lead to performance issues or safety hazards. This complexity necessitates specialized skills and a deep understanding of Tesla’s unique design philosophy.

When a Tesla endures an auto collision or needs significant structural repairs, it’s not merely about fixing visible dents or cracks. It involves carefully calibrating the vehicle’s sensors, adaptive suspension systems, and advanced driver-assistance features (ADAS) to ensure they function optimally post-repair. This level of precision work demands highly trained technicians who can skillfully perform car paint services while preserving the vehicle’s overall performance and safety characteristics, setting Tesla structural integrity repair apart from conventional auto collision centers.

Tesla’s commitment to innovation in vehicle design presents unique challenges when it comes to structural integrity repair. The brand’s advanced technology and distinctive architectural features require specialized knowledge and precise techniques for successful repairs. As Tesla continues to push boundaries, so too must the standards for structural integrity maintenance, ensuring that these complex vehicles remain safe and reliable for their owners. Efficient handling of Tesla structural integrity repair is paramount in the ever-evolving automotive landscape.